|

Discussion Link

A couple of you have asked about the VS conversion to my Nova 3000 on my Shop Pics thread, so here is a WIP. It is based on a conversion done by Steve Harder which I saw on the Nova Owners forum.

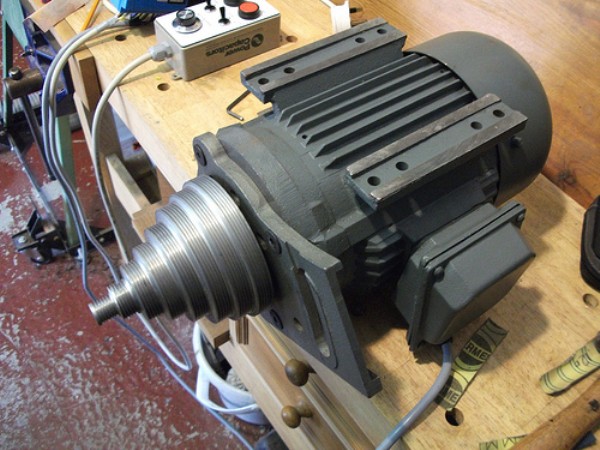

Inverter, control box and motor wired up and on the bench for testing.

Headstock endplate removed ready to remove the motor and mounting plate:-

Checking the gap between the pulley and the plate to ensure the pulleys align when re-assembled.

Old motor, pulley and mounting plate removed:-

Pulley removed and ready to remove the mounting plate which is held in place by eight 6mm csk. screws.

Mounting plate fitted to new motor using the four larger mounting holes and four 3/8" UNC x 1 1/4" csk. screws. Note that motor is mounted "upside down" so that the mounting foot, which is not used in this application, can be used to mount the control box.

Pulley fitted to new motor. The motor shaft was exactly 0.875", the pulley slightly under size. Strictly speaking I should have had the pulley machined to fit, but the difference was so slight I simply reduced the size of the shaft with j/flex abrasive. The keyways were different sizes too so I had to make up a hybrid with an old key and a bit of careful filing:-

New motor, pulley and mounting plate fitted and ready to test.

Headstock fully re-assembled.

Inverter mounted on the wall. It will eventually go in a proper enclosure to protect it from dust, but this will do for now.

Control box mounted on an mdf support bolted to the motor "foot.

Job done.

I am really pleased with the result, I now have eight variable speed ranges and the whole lathe is much smoother and quieter. |

|